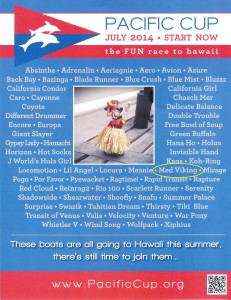

While attending the Pacific Offshore Academy III, I noticed a poster with the names of the boat already signed up for the race. Med Viking was obviously listed.

Monthly Archives: January 2014

Pacific Offshore Academy III

Yesterday was the third seminar organized by the race committee. I had to fly out of LAX because there are very few flights between Orange County and Oakland on a Sunday of winter. There was no strike of the BART like last time but I decided to still rent a car since it makes the logistic a little bit easier.

Subjects were varied :

- Optimizing your boat (Racing or Cruising)

- Practice with Crew

- Provisioning, Gear and Food Storage

- Getting home: Shipping vs Sailing

The content was on a light side but it was still nice to meet some people. I was able to take an earlier flight (7:55PM instead of 8:50PM) out of Oakland so I was home by 10PM.

Another 25%

We spent another weekend putting the rail on the port side. We managed to do it in one day of work instead of one and half for the first section.

Bob had spent a lot of time preparing for the day and gave me his spot at the dock so Med Viking could be on the right side of the dock.

After work it was time to relax.

The best part: Dianna cooked a meal of fresh Ahi Tuna. That was delicious.

Photo credit: Dianna

We got serious

As promised in my previous post, Bob and I got really serious and installed 25% (one section) of the new toe rail. As always, preparation was the key to success. We spent Saturday bending the aluminum and drilling the deck in preparation for the actual fitting on Sunday. Everything worked as planned. We drilled undersized holes and “threaded” the screws through the fiberglass. We just inserted a few nuts to hold the rail in place but most of them were just holding the rail by the thread (a trick that Robb Walker taught me)

After dry fitting the toe rail, we removed it. We found out that the aluminum has no memory. The extrusion came back straight as an arrow! We then drilled the holes to size, cleaned up everything and put masking tapes on the holes as the nights are quite humid. Another nice trick: on Saturday night I glued 40 fender washers to 40 nuts with super glue. That helped holding them together and making sure that the nuts would not fall into the socket.

On Sunday, with the help of Dianna, Paul, Glen and Judy, we were able to bend the rail back into place. Only this time we had a few beads of Life Calk as sealant. A few screws were really hard to reach from below but we managed to get all of them. We were very happy with the result.

We still need to add a notch “somewhere” for the over sized cleats that came with the boat.

The icing on the cake was that Bob found out (at the end of the day!) that we can just unscrew the top of the cabinets to reach basically everywhere. I will still need to use my aluminum stick extension (socket taped at the end) but that removes the last worry I had (especially in the galley).